| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Tengtian

Model Number : ERW32

Certification : CE, ISO9001, BV

Place of Origin : Hebei

MOQ : 1 Set

Price : $100000 to $1 million

Payment Terms : L/C, T/T

Supply Ability : 50 Sets/Year

Delivery Time : 60 work days

Packaging Details : Export waterproof and Seaworthy packing.

Product name : High Precision Steel Tube Mill Production Line Worm Gearing Friction Saw

Running speed : Max.120m/min

Pipe shape : Round, Square & Rectangular

Pipe Diameter : 12 - 32mm

Max.Thickness for Square Pipe : 0.5-1.5mm

Welding Type : High Frequency Welding

Cutting Saw : Friction Saw Cutting

Max.Thickness for Round Pipe : 0.5-2.0mm

Keyword : Precision Tube Mill

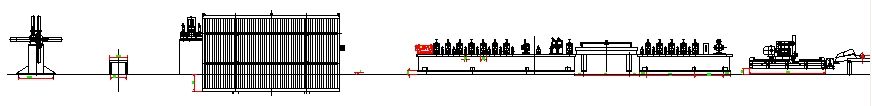

ERW32 high precision steel tube mill production line

The mill is used to manufacture of round pipe of Φ12mm-Φ32mm with thickness of 0.5mm-2.0mm from cold-rolled and hot-rolled coil strip by means of unclosed tubular blank with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths.

Product advantage:

Production Process

Scroll up → Uncoil → Flattening → End Shear & Butt Welding → Accumulator → Forming → High-frequency induction welding→ Removing external burr → Cooling → Sizing → Cutting → Checking & Collecting → Accessing Warehouse

Specifications:

1. Raw Material: HRC, CRC, Galvanised Coil

2. Production Range:

Round Pipe: 12 - 32mm; Thickness: 0.5-2.0mm

Square Pipe: 10*10 - 25*25mm; Thickness: 0.5-1.5mm

3. H.F. Welder: GGP150Kw Solid State High Frequency Welder

4. Line Spees: Max. 120m/min

5. Tube Length: 4-12m

6. Cutting Accuracy: ±3mm

7. Electric installed capacity: appro. 300KW

8. Size of whole line: about 50X5m

High‐frequency welded tube mill line is designed to produce round tube diameter of 8.0 – 32.0mm, and wall thickness of 0.4 ‐1.6mm.This line utilizes roll forming to process steel strip into various shapes. Using high frequency induction heating, this line is capable of producing section material of various diameters and sizes by squeezing weld seam together into closed shape. The application of advanced aperture technology, PLC automatic control system and British Eurasia Digital speed‐regulating unit ensure that the production line works reliably and operates and maintains easily.

Coil loading—Uncoiling‐Strip joining—accumulator—Forming,‐HF Welding–Bead Remover ‐Cooling—Sizing & straightening‐Measuring roll—Flying saw cutting—Double dumps Run out conveyor

If you have any interested here, please don't hesitate, we are here happy to assist you.

|

|

High Precision Steel Tube Mill Production Line Worm Gearing Friction Saw Images |